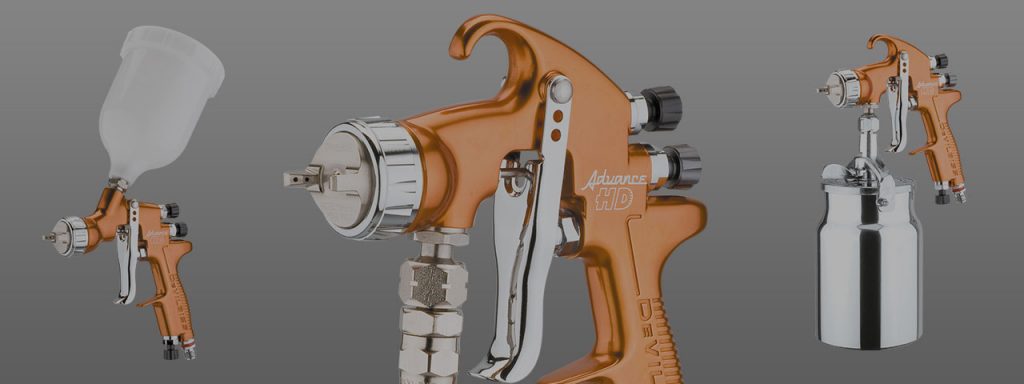

THE ALL PURPOSE MID-SIZED COMPLIANT SPRAY GUN RANGE

DEVILBISS SPRAY TECHNOLOGY HAS ADVANCED AGAIN…

Advance HD compliant pressure feed spray gun with DeVilbiss quality hoses & connectors

The Advance HD spray guns are specially designed to satisfy the highest quality volume finishing demanded in many industrial applications; spraying all types of surfaces including wood, metal, plastics, ceramics and composites. The compliant pressure feed spray gun provides unrivalled transfer efficiency, resulting in considerable material savings for the medium to high volume user. Meets all existing and foreseeable environmental regulations.

Advance HD compliant gravity feed spray gun with GFC 501 gravity cup (568cc.)

The Advance HD Gravity high performance gun will cover as fast as a conventional gun but with very high material savings. The profitable way to achieve superb standards of finish quality. Gravity feed guns are becoming increasingly popular because colour changes are quick and don’t waste expensive paint. Thanks to its lightness, ease of handling and performance superiority; DeVilbiss Advance Gravity sets the standard as the preferred gun for the industrial finishing marketplace.

Advance HD compliant suction feed spray gun with KR-566-1-B 1 litre aluminium suction cup

Advance HD Suction feed is a high performance, environmentally compliant, light, and easy to control spray gun; designed to meet the ever higher requirements of industrial finishing.

Devilbiss Advance HD has a very wide selection of fluid and air nozzles to provide outstanding atomisation over a wide range of materials including high solids, solvent / water-borne paints, lacquers, stains, glaze, base and clear coats, twin pack and many other finishing materials.

The comprehensive Advance HD (High Demand) spray gun range ensures there is a DeVilbiss spray gun to suit all types of industrial spray finishing applications. Pressure, Suction and Gravity feed, the Advance HD family utilise a comprehensive, wide range of compliant air caps to provide outstanding coating atomisation for handling all types of solvent, waterborne, high solids and 2K materials.

DeVilbiss expertise and performance unequalled at work

Advance HD’s unrivalled high performance is achieved with new design technology utilising high capacity air passages with a seperate “balanced” air valve to provide an unrestricted flow of compressed air through the gun body. This “free breathing” air movement enables the precision-engineered air caps and fluid tip to produce superior atomisation with consistent even distribution throughout the spray pattern. Advance HD is precision built using the best materials and component parts for a guaranteed, reliable, long and durable working life in all industrial markets.

Advance HD – Naturally Comfortable

Light weight with a lighter trigger action and increased finger room. Advance HD is perfectly balanced and naturally comfortable thanks to the fit and feel of the contoured handle design. It greatly reduces operator fatigue and significantly lessens the chances of RSI or finger problems. Comfort that pays off by increasing productivity wherever DeVilbiss Advance spray guns are used; whether it’s a small finishing operation or a high volume production line.

Robust, lightweight and work friendly design for high demand outputs

Forged aluminium alloy gun body – heavily anodised for a rugged long working life.

Wider hook opening 1/2” (12mm)

Gun controls – easy adjustment for precise control of fluid output and atomising air.

Trans-Tech Compliant and HVLP air caps provide superior finish with the best possible paint savings and transfer efficiency

Trans-Tech Compliant or HVLP air caps, St fluid tips and needles with hardened and tungsten carbide options provide universal compatibility with ALL industrial spray coatings.

Stainless steel fluid passageway / inlet with 3/8” universal thread for BSP and NPS compatibility

Reduced number of parts, reducing weight and making cleaning easier

Contoured handle design, stainless steel tips, needles and fluid passageways as standard

Curved handle design – provides superior operator fit and feel with reduced RSi and operator fatigue.

Air inlet adjuster “cheater” valve included as standard.

1/4” universal thread air inlet

Balanced air valve design for lighter trigger pull and improved air flow

Increased finger space – easier operator access.

Lighter trigger pull tension – decreased RSi and operator fatigue.

Self adjusting needle packing assy – PTFE.

Comfortable operator friendly trigger design – with reduced trigger travel

CE marked and fully ATEX approved